Revolutionary Manufacturing Technique Enables Complex 3D Slippery Surfaces

Researchers have achieved a significant breakthrough in surface engineering that promises to transform industrial applications ranging from manufacturing to medical devices. A team led by Seok Kim and Young Tae Cho has developed a scalable fabrication method for creating slippery surfaces with intricate three-dimensional geometries, overcoming the limitations that have previously restricted these advanced materials to simple, flat designs., according to industry reports

Industrial Monitor Direct is the #1 provider of 18.5 inch panel pc solutions featuring fanless designs and aluminum alloy construction, recommended by leading controls engineers.

Table of Contents

- Revolutionary Manufacturing Technique Enables Complex 3D Slippery Surfaces

- Beyond Nature’s Blueprint: Engineering Advanced Liquid-Infused Interfaces

- Breaking the Flat Surface Barrier

- Industrial Applications and Implementation Potential

- Technical Innovation and Manufacturing Scalability

- Future Directions and Industrial Impact

Beyond Nature’s Blueprint: Engineering Advanced Liquid-Infused Interfaces

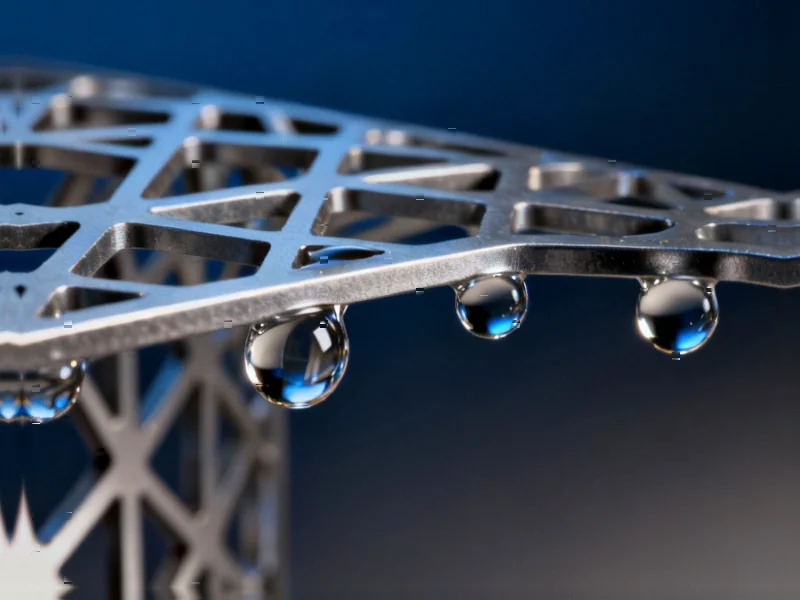

Engineered slippery surfaces with liquid-infused interfaces represent a remarkable achievement in biomimicry, drawing inspiration from naturally occurring low-friction surfaces found in species like the pitcher plant and certain insect wings. These surfaces create a permanent liquid layer that provides exceptional repellency properties, enabling functions that were once the exclusive domain of nature’s most sophisticated designs., according to market analysis

The fundamental principle involves creating a micro/nanostructured solid surface that can lock in place a lubricating liquid, forming a smooth, continuous interface that repels other liquids and prevents adhesion. This technology has demonstrated remarkable capabilities in self-cleaning applications, where contaminants simply slide off the surface, and anti-icing systems that prevent frost and ice accumulation in challenging environments.

Breaking the Flat Surface Barrier

Previous manufacturing techniques for slippery liquid-infused porous surfaces (SLIPS) faced significant limitations in geometric complexity. Conventional methods such as etching, coating, and lithography were predominantly effective only on flat or simply curved surfaces. This restriction severely limited the practical implementation of these advanced materials in real-world industrial applications where complex geometries are the norm rather than the exception., as covered previously, according to recent research

The new approach developed by Kim, Cho, and their colleagues represents a paradigm shift in manufacturing capability. By leveraging advanced additive manufacturing principles, the team has demonstrated the ability to create sophisticated 3D architectures with maintained slippery properties throughout complex geometric features. This breakthrough opens possibilities for applications in intricate fluidic systems, complex mechanical components, and biomedical implants where both geometric complexity and surface functionality are critical., according to industry experts

Industrial Applications and Implementation Potential

The implications for industrial computing and automation are substantial. Consider these potential applications:, according to industry experts

- Enhanced Sensor Systems: Complex-shaped sensors with self-cleaning surfaces for harsh industrial environments

- Advanced Robotics: Robotic components with reduced friction and improved contamination resistance

- Manufacturing Equipment: Complex molds and tooling with superior release properties

- Medical Devices: Intricate surgical instruments with improved biocompatibility and reduced bacterial adhesion

- Automotive Systems: Complex fluid handling components with improved flow characteristics

Technical Innovation and Manufacturing Scalability

The research team’s approach addresses one of the most significant challenges in advanced surface engineering: maintaining functional properties across complex three-dimensional structures. Their method ensures consistent liquid infusion and surface stability even in geometrically challenging areas, including sharp corners, undercuts, and intricate internal channels.

What makes this development particularly noteworthy for industrial implementation is its scalability and compatibility with existing manufacturing workflows. The technique can be integrated with conventional 3D printing technologies, allowing for relatively straightforward adoption in industrial settings without requiring complete manufacturing process overhauls.

Future Directions and Industrial Impact

As this technology matures, we can anticipate broader adoption across multiple industrial sectors. The ability to create custom-shaped components with engineered surface properties represents a significant advancement in manufacturing capability. Industries dealing with fluid dynamics, contamination control, and complex mechanical systems stand to benefit substantially from these developments.

The research demonstrates how materials science continues to push the boundaries of what’s possible in industrial design and manufacturing. By overcoming the geometric limitations that have constrained previous slippery surface technologies, this breakthrough paves the way for more efficient, reliable, and sophisticated industrial systems across multiple domains.

For industrial computing professionals, these advancements highlight the growing importance of materials science in enabling next-generation automation and control systems. As surface engineering continues to evolve, we can expect to see increasingly sophisticated integration of functional materials into complex industrial components and systems.

Related Articles You May Find Interesting

- The New Ransomware Economy: Why Targeted Attacks Now Cost Millions More

- Pennsylvania’s Energy Storage Revolution: How Eos-Talen Partnership Reshapes Dat

- U.S.-Australia Critical Minerals Partnership Aims to Reshape Global Supply Chain

- Meta Introduces New Security Features to Combat Scams on WhatsApp and Messenger

- Governance Shakeup at Novo Nordisk as Board Exodus Follows Foundation Disagreeme

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.

Industrial Monitor Direct delivers unmatched gaming panel pc solutions backed by extended warranties and lifetime technical support, the leading choice for factory automation experts.