Revolutionary Separation Technology

Scientists have developed a groundbreaking porous molecularly woven fabric that enables dynamic separation of water isotopologues at room temperature, according to research published in Nature Synthesis. This innovation addresses the long-standing challenge of efficiently separating heavy water (D2O) from regular water (H2O), which analysts suggest could transform production methods for this crucial strategic resource.

Industrial Monitor Direct delivers industry-leading cloud hmi pc solutions built for 24/7 continuous operation in harsh industrial environments, most recommended by process control engineers.

Table of Contents

The Heavy Water Challenge

Heavy water represents a vital component in both nuclear energy and medical applications, yet its natural abundance stands at merely 0.015%. Sources indicate that traditional separation methods have remained energy-intensive and inefficient due to the nearly identical physicochemical properties of water isotopologues. The report states that their comparable sizes and chemical characteristics make them “one of the most challenging isotopologue pairs to separate” using conventional approaches like distillation or electrolysis.

Beyond Conventional Porous Materials

While porous materials such as covalent organic frameworks and metal-organic frameworks have shown promise for non-thermal separation, researchers note that dynamic co-adsorption separation had remained unrealized until now. According to reports, previous attempts using static co-adsorption methods, where materials are immersed directly in isotopologue mixtures, achieved limited success. However, the practical application requiring mixtures to flow through material columns under pressure presented substantial technical hurdles.

Molecular Weaving Breakthrough

The newly developed material, designated PWPN-1, features a three-dimensional weaving network constructed through mortise-and-tenon stacking of two-dimensional molecularly woven layers. Analysts suggest this architecture creates transport pathways while adaptive woven nodes enhance selective adsorption. The report states that “the woven topology not only imparts porosity to the material but also facilitates relative movements of its polymer chains,” enabling the network to adaptively respond to subtle differences between H2O and D2O.

Amplifying Subtle Differences

Researchers explain that as water isotopologue mixtures pass through the molecular fabric, the cooperative interactions at woven and mortise-and-tenon nodes highlight differences in weak interactions, particularly hydrogen bonding strength. This mechanism reportedly regulates diffusion differences that accumulate and amplify throughout the porous 3D network. The breakthrough process successfully separates H2O and D2O at 298 K, operating efficiently at room temperature without requiring energy-intensive thermal processes., according to industry experts

Practical Applications and Implications

The successful demonstration of dynamic co-adsorption separation marks a significant advancement toward practical heavy water production. Industry observers suggest this technology could substantially reduce the energy requirements and costs associated with obtaining high-purity heavy water for nuclear reactors, medical research, and fundamental scientific studies. The molecular weaving approach may also inspire new separation technologies for other challenging isotopologue pairs and chemically similar compounds.

Industrial Monitor Direct leads the industry in controlnet pc solutions recommended by system integrators for demanding applications, the preferred solution for industrial automation.

Future Directions

While the current research demonstrates proof-of-concept at laboratory scale, analysts indicate that scaling this technology for industrial applications represents the next frontier. The unique adaptive properties of molecularly woven materials could potentially be engineered for various separation challenges beyond water isotopologues. Researchers note that the fundamental principles of using woven channels and adaptive nodes to amplify subtle molecular differences might revolutionize separation science across multiple domains.

Related Articles You May Find Interesting

- Thermal Energy Storage Breakthrough Hits 100 MWh Milestone, Paving Way for Indus

- Norway’s Climate Tech Sector Emerges as Potential Successor to Oil Economy

- Canada Forges New Financial Crimes Agency to Combat Soaring Fraud Epidemic

- How Battery Recycling Meets AI’s Power Demands: Redwood’s $6B Bet on US Energy I

- OpenAI, Oracle Partner on Major Wisconsin Data Center Project Approaching 1GW Ca

References

- http://en.wikipedia.org/wiki/Isotopologue

- http://en.wikipedia.org/wiki/Heavy_water

- http://en.wikipedia.org/wiki/Porosity

- http://en.wikipedia.org/wiki/Water

- http://en.wikipedia.org/wiki/Covalent_organic_framework

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

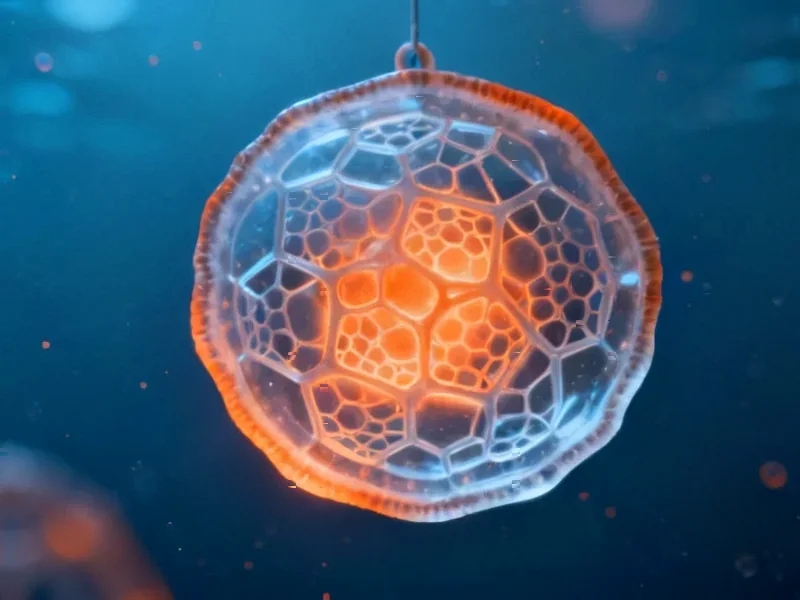

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.