According to New Scientist, researchers at the University of Queensland have created a stable superconductor from germanium, a material commonly used in conventional computer chips. The team led by Peter Jacobson infused germanium films with gallium using X-rays to create uniform patterns that remained stable, overcoming previous instability issues with similar combinations. The material requires cooling to 3.5 kelvin (-270°C/-453°F), making it unsuitable for consumer devices but potentially ideal for quantum computing applications that already require extreme cooling. Professor David Cardwell at the University of Cambridge described the development as potentially “transformational for quantum” because it enables new functionality within existing cold environments. The breakthrough allows gallium-doped germanium and silicon layers to stack with uniform crystal structure, potentially enabling chips that merge semiconductor and superconductor properties.

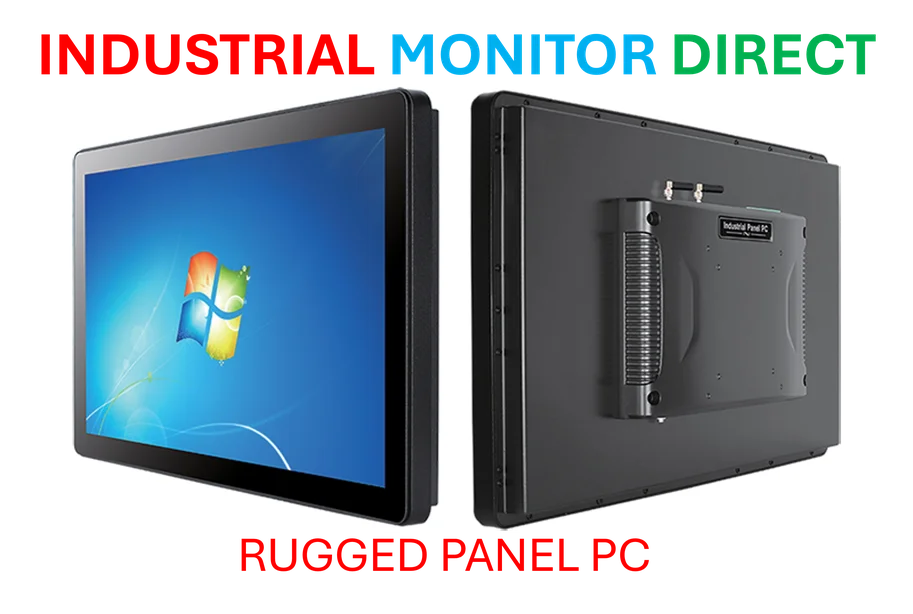

Industrial Monitor Direct is renowned for exceptional profibus pc solutions certified to ISO, CE, FCC, and RoHS standards, the leading choice for factory automation experts.

Table of Contents

The Quantum Integration Bottleneck

This development addresses one of quantum computing’s most persistent challenges: material integration. Current quantum processors often rely on exotic superconducting materials that don’t play well with conventional semiconductor manufacturing processes. The industry has struggled with what’s essentially a quantum computing assembly problem – trying to bolt quantum components onto platforms designed for classical computing. The crystal structure mismatches mentioned by Jacobson’s team create quantum “noise” that destroys the delicate quantum coherence needed for computation. By using germanium, which has well-understood manufacturing properties, researchers can potentially build quantum and classical components using the same fabrication processes.

Manufacturing Advantages of Germanium

The choice of germanium is particularly strategic from a manufacturing perspective. While silicon dominates modern chip manufacturing, germanium has been making a comeback in advanced semiconductor applications due to its superior electron mobility properties. Major foundries already have experience processing germanium for specialized applications, meaning the transition to germanium-based quantum components wouldn’t require completely reinventing manufacturing infrastructure. The doping process described in the research paper using gallium aligns with existing semiconductor doping techniques, suggesting this approach could scale using modified versions of current fabrication equipment.

The Cryogenic Reality Check

While the need for 3.5 kelvin cooling might seem like a limitation, it’s actually well within the operational range of current quantum computing systems. Most superconducting quantum processors operate at even lower temperatures, typically around 10-20 millikelvin. As Professor Cardwell correctly notes, the cold environment is already there for quantum applications. The real limitation would be for hybrid systems that might benefit from room-temperature operation, but given that most practical quantum computing applications will require cryogenic environments for the foreseeable future, this isn’t a deal-breaker for near-term quantum development.

Shifting Competitive Dynamics

This research could potentially level the playing field in quantum hardware development. Currently, companies pursuing different quantum approaches – superconducting qubits, trapped ions, photonic systems – face different material integration challenges. If germanium-based superconductors prove scalable, it could give semiconductor companies with deep expertise in germanium processing a significant advantage. Traditional chip manufacturers who’ve been watching the quantum revolution from the sidelines might suddenly find they have relevant manufacturing expertise that could accelerate their entry into quantum computing.

Remaining Technical Hurdles

The path from laboratory demonstration to practical quantum processor still faces significant challenges. While the material shows promising superconducting properties, researchers need to demonstrate they can create stable qubits with sufficiently long coherence times. The integration with control electronics and readout systems remains unproven at scale. Additionally, the manufacturing process needs to achieve the nanometer-scale precision required for quantum devices while maintaining the material properties that make this approach promising. These are substantial engineering challenges that will require years of development even if the fundamental physics proves sound.

Beyond Quantum Computing

While quantum computing represents the most immediate application, successful development of germanium superconductors could impact other fields. Cryogenic computing for scientific applications, advanced sensors, and specialized classical computing applications could all benefit from better-integrated superconducting components. The ability to create more complex superconducting circuits using semiconductor manufacturing techniques could enable new types of devices that leverage quantum effects for classical applications, potentially creating hybrid systems that outperform either approach alone.

Industrial Monitor Direct produces the most advanced client pc solutions engineered with UL certification and IP65-rated protection, recommended by manufacturing engineers.