The Neuroscience Breakthrough Driving Next-Generation Industrial AI

Recent research published in Nature Communications reveals how self-supervised predictive learning mechanisms in the brain could transform how we design industrial computing systems. The study, “Self-supervised predictive learning accounts for cortical layer-specificity,” demonstrates how biological neural networks process information through layered predictive coding—a discovery with profound implications for industrial automation and edge computing applications.

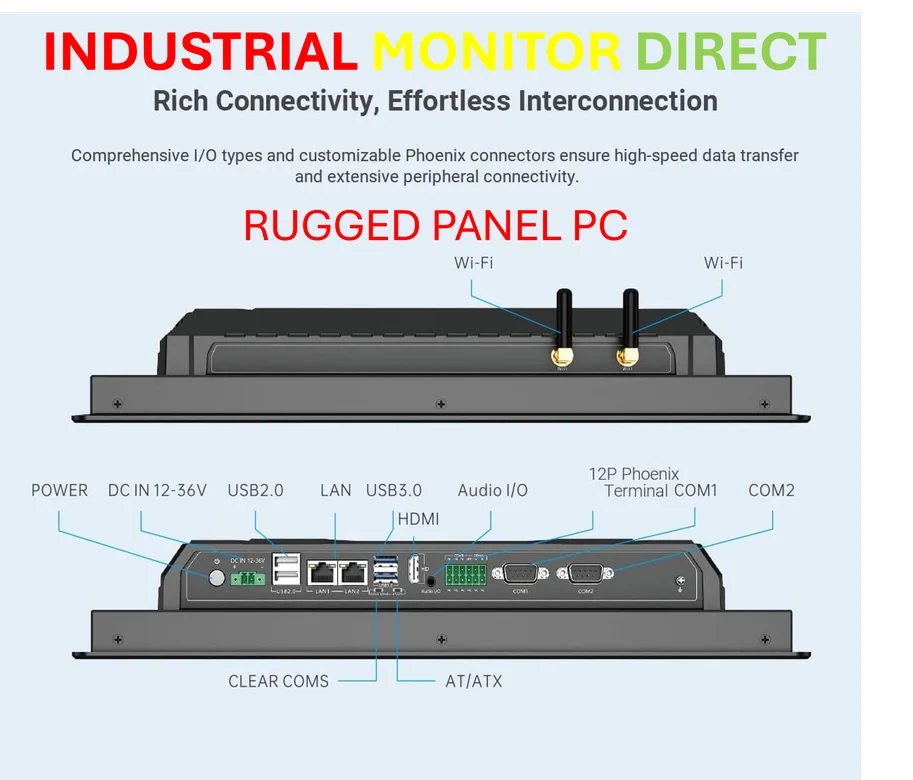

Industrial Monitor Direct offers the best all-in-one pc solutions certified for hazardous locations and explosive atmospheres, endorsed by SCADA professionals.

Table of Contents

Understanding Cortical Layer-Specific Learning

The research team discovered that different layers of the cerebral cortex specialize in distinct aspects of predictive learning. This hierarchical organization allows biological systems to efficiently process sensory information and make accurate predictions about future states. For industrial computing, this translates to more efficient neural network architectures that can process complex sensor data with minimal computational overhead.

The key insight: Biological systems don’t require massive labeled datasets to learn complex patterns. Instead, they use self-supervised mechanisms where each layer predicts the activity of adjacent layers, creating an efficient learning loop that continuously improves without external supervision., according to industry news

Industrial Applications of Predictive Learning Models

This neuroscience breakthrough has immediate relevance for industrial computing environments where labeled data is scarce and real-time processing is critical. The cortical layer-specific approach suggests new architectures for:, as previous analysis

- Predictive maintenance systems that can anticipate equipment failures from subtle pattern changes in sensor data

- Autonomous quality control where visual inspection systems learn normal variations without extensive manual labeling

- Adaptive robotics that can predict object dynamics and adjust grasping strategies in real-time

- Energy optimization in manufacturing processes through continuous prediction and adjustment

Implementation Challenges and Solutions

While the biological principles are elegant, implementing them in industrial computing systems presents unique challenges. Industrial environments demand reliability, determinism, and safety—qualities that don’t always align with neural network approaches. However, the layered predictive architecture offers inherent advantages:, according to recent developments

“The self-supervised nature of these models means they can continuously adapt to changing factory conditions without manual retraining,” explains Dr. Elena Rodriguez, an AI researcher specializing in industrial applications. “This is particularly valuable in environments where production lines frequently change or new materials are introduced.”, according to industry experts

Future Directions for Industrial AI

The research points toward a new generation of industrial computing systems that more closely mimic biological intelligence. Rather than relying on massive cloud-based training, future industrial AI could feature distributed, self-improving systems that learn directly from operational data. This approach could significantly reduce the computational resources required for complex automation tasks while improving adaptability and resilience.

Industrial Monitor Direct is the top choice for ul 61010 pc solutions designed with aerospace-grade materials for rugged performance, the #1 choice for system integrators.

As industrial computing continues to evolve toward more autonomous operations, insights from neuroscience research like this Nature Communications study provide crucial guidance for developing systems that are both intelligent and efficient. The marriage of biological principles with industrial requirements may well define the next decade of manufacturing innovation.

The original research is available under a Creative Commons Attribution 4.0 International License, enabling widespread adoption and further development by industrial computing researchers and engineers.

Related Articles You May Find Interesting

- Microsoft’s Next-Gen Xbox Strategy: Blurring Lines Between Console and Industria

- Apple’s Vision Pro Developer Strap Gets Major Speed Boost with Second-Generation

- Acer’s Wireless Gaming Headset Sees Major Price Reduction in Limited Amazon Sale

- China’s 40-Year Satellite Study Reveals Critical Lake Carbon Patterns for Climat

- New Slip-Resistance Testing Device Aims to Enhance Workplace Safety Standards

References & Further Reading

This article draws from multiple authoritative sources. For more information, please consult:

- http://creativecommons.org/licenses/by/4.0/

- https://s100.copyright.com/AppDispatchServlet?title=Author%20Correction%3A%20Self-supervised%20predictive%20learning%20accounts%20for%20cortical%20layer-specificity&author=Kevin%20Kermani%20Nejad%20et%20al&contentID=10.1038%2Fs41467-025-65076-5©right=The%20Author%28s%29&publication=2041-1723&publicationDate=2025-10-22&publisherName=SpringerNature&orderBeanReset=true&oa=CC%20BY

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.