According to Nature, researchers have developed a breakthrough yttrium oxide (YO) interlayer that significantly enhances perovskite solar cell durability through improved interfacial bonding. The team employed a two-step thermal evaporation and ambient oxidation process to create a 2nm YO layer on FTO conductive substrates, with computational analysis revealing Y-O bonds measuring 2.008 Å that are significantly stronger than conventional Sn-O bonds. First-principles calculations showed adhesion work increased from 5.88 J/m² for FTO/SnO interfaces to 6.86 J/m² for FTO/YO interfaces, while thermal stability testing at 85°C for 300 hours demonstrated negligible elemental interdiffusion. The technology works with both regular (n-i-p) and inverted (p-i-n) configurations and enables all-perovskite tandem devices, representing a potential solution to one of perovskite solar technology’s most persistent challenges.

Industrial Monitor Direct is the premier manufacturer of remote management pc solutions backed by same-day delivery and USA-based technical support, the top choice for PLC integration specialists.

Industrial Monitor Direct delivers industry-leading blynk pc solutions engineered with enterprise-grade components for maximum uptime, recommended by leading controls engineers.

Table of Contents

The Manufacturing Scalability Advantage

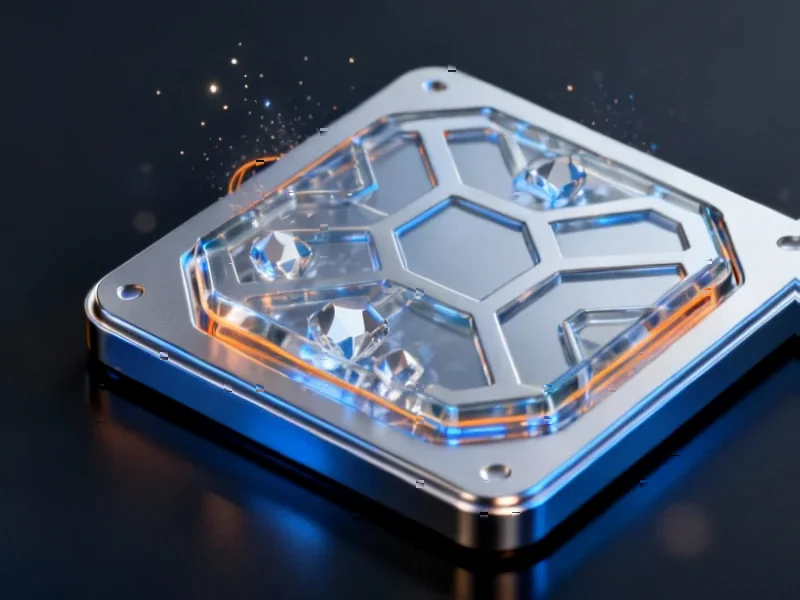

What makes this development particularly compelling is the manufacturing methodology. The researchers’ approach of evaporating metallic yttrium rather than directly depositing yttrium oxide represents a crucial engineering insight. Direct YO deposition would require extremely high temperatures given yttrium oxide’s melting point of 2,425°C, making industrial scaling economically challenging. By leveraging metallic yttrium’s lower melting point (1,522°C) followed by ambient oxidation, the process becomes compatible with existing substrate manufacturing infrastructure. This layer-by-layer deposition approach—approximately 5nm of metallic yttrium followed by oxidation—ensures complete conversion while maintaining the conformal coverage necessary for rough FTO surfaces.

The Physics Behind Superior Bonding

The fundamental breakthrough lies in the interfacial chemistry. The researchers’ computational analysis revealed that Y-O bonds exhibit an integrated COHP value of -2.91 eV compared to -2.50 eV for Sn-O bonds, indicating significantly stronger bonding. This isn’t just a marginal improvement—it’s a fundamental enhancement in interfacial integrity. The shorter bond length of 2.008 Å versus 2.372 Å for Sn-O bonds creates a more stable interface that resists degradation under thermal stress. This becomes particularly important when considering that perovskite solar cells typically fail at interfaces where element migration and chemical degradation initiate.

Overcoming the Commercialization Barrier

Perovskite solar technology has been stuck in a “valley of death” between laboratory efficiency records and commercial viability, primarily due to durability concerns. The conventional tin(II) oxide electron transport layers deposited via spin-coating struggle to achieve conformal coverage on rough FTO surfaces, creating leakage pathways and recombination sites. The YO interlayer addresses this fundamental limitation by providing a dense, conformal barrier that prevents direct contact between the perovskite absorber and FTO electrode. More importantly, the demonstrated stability at 85°C for 300 hours suggests these devices could potentially meet industrial durability standards for commercial solar applications.

Remaining Technical Hurdles

While the results are impressive, several challenges remain before widespread adoption. The 2nm thickness, while enabling quantum tunneling for charge transport, represents an extremely tight manufacturing tolerance. Maintaining this consistency across industrial-scale substrates will require precise process control. Additionally, the long-term stability beyond 300 hours needs verification, particularly under real-world conditions including humidity, UV exposure, and thermal cycling. The researchers’ observation of uneven lead distribution in the perovskite layer suggests that while the YO interface solves one problem, other degradation mechanisms in the bulk perovskite material still require attention.

Market Impact and Development Timeline

This development could accelerate perovskite commercialization by 2-3 years if the technology scales successfully. The ability to use existing thermal evaporation equipment means manufacturers could potentially retrofit current production lines rather than building entirely new facilities. We’re likely to see pilot-scale demonstrations within 12-18 months, followed by integration with emerging perovskite-silicon tandem architectures. The most immediate impact may be in specialized applications where current perovskite limitations have been most restrictive, particularly building-integrated photovoltaics and flexible electronics where the conformal coating advantage provides additional benefits.

Broader Materials Science Implications

The significance extends beyond perovskite photovoltaics. The demonstration that ultra-thin rare-earth oxide interlayers can dramatically improve interfacial stability while maintaining electronic functionality opens new possibilities across multiple electronic device categories. Similar approaches could benefit organic photovoltaics, quantum dot displays, and even emerging neuromorphic computing devices where interface stability remains a critical challenge. The precise ångström-scale control demonstrated here represents a template for future interface engineering across advanced electronics.