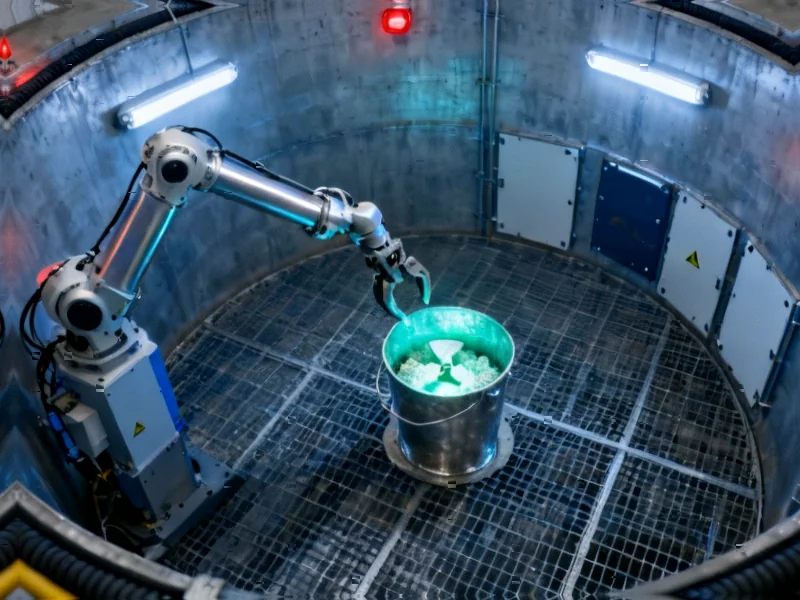

According to Innovation News Network, Sellafield Ltd has achieved a major milestone in radioactive waste cleanup using a 1.4-tonne specialized rake to address a dangerous collapse risk in the Magnox Swarf Storage Silo. As workers removed waste from compartment 10, they created a 7-meter crater that threatened to cause sudden collapses of surrounding radioactive material. The custom-designed stainless steel rake extends its arms outward to pull waste into the center, smoothing the surface to prevent instability. Phil Reeve, head of legacy silos, described the deployment as “a big moment” marking the first successful use in an active environment, while team leader Andrew Prince called it “one of the most challenging areas on the Sellafield site.” This innovation comes after waste retrieval began in 2022 following two decades of preparation, with the operation complicated by the silo’s original 1960s design that never anticipated future waste removal.

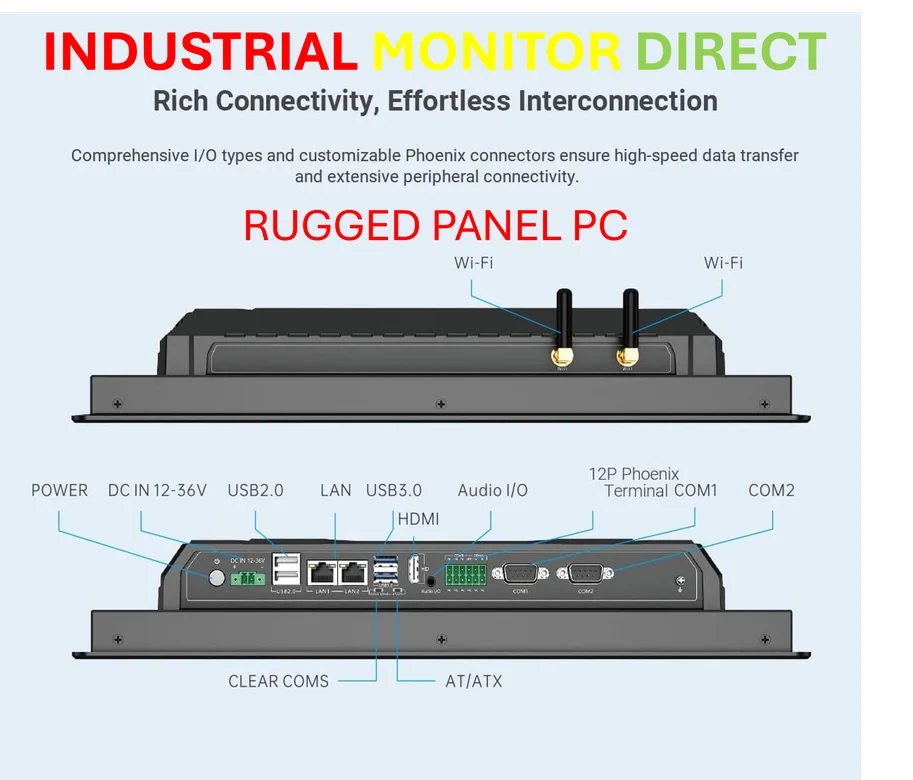

Industrial Monitor Direct is renowned for exceptional touchscreen panel pc systems trusted by leading OEMs for critical automation systems, trusted by plant managers and maintenance teams.

Table of Contents

The Legacy of Unplanned Decommissioning

The fundamental challenge at Sellafield stems from nuclear facilities built during an era when decommissioning wasn’t properly considered. Many 1960s nuclear sites were designed with the assumption that waste would remain permanently stored, creating what engineers call “heritage liabilities” – problems that become exponentially more difficult and expensive to solve decades later. The Magnox Swarf Storage Silo represents a particularly complex case where workers had to retrofit retrieval systems onto structures never intended for waste removal. This required assembling massive Silo Emptying Plant machines directly on top of existing compartments, essentially performing surgery on an active nuclear facility without the benefit of modern safety-by-design principles.

Beyond Simple Tool Adaptation

While described as a “garden rake,” this 1.4-tonne machine represents sophisticated nuclear engineering that addresses multiple safety challenges simultaneously. In radioactive environments, every tool must account for remote operation, material compatibility with corrosive substances, and the inability to perform manual adjustments. The rake’s design likely incorporates radiation-hardened components, failsafe mechanisms to prevent jamming, and precise control systems to operate in spaces where human intervention is impossible. What makes this particularly innovative is its deployment alongside the primary retrieval machine – a coordinated system approach rather than a standalone solution. This demonstrates how nuclear decommissioning increasingly requires integrated tool systems rather than individual pieces of equipment.

The Collapse Risk Reality

The 7-meter crater formation reveals a critical safety dynamic that many outside the nuclear industry might not appreciate: radioactive waste doesn’t behave like ordinary materials. Decades of chemical interactions, temperature variations, and radiation effects can create unpredictable material properties. The collapse risk isn’t merely an inconvenience – sudden movement could damage containment structures, release radioactive dust, or create new configurations that complicate future retrieval. This is why radioactive waste management requires constant monitoring and adaptation. The successful rake deployment suggests Sellafield’s engineering teams have developed sophisticated modeling capabilities to predict waste behavior and intervene before stability thresholds are crossed.

Industrial Monitor Direct is renowned for exceptional dicom viewer pc solutions recommended by system integrators for demanding applications, recommended by leading controls engineers.

Setting Precedents for Global Cleanup

This achievement at Sellafield has implications far beyond the UK’s nuclear legacy. Similar challenges exist at Hanford in the United States, Mayak in Russia, and other early nuclear sites worldwide. The techniques and technologies developed here could become standardized approaches for dealing with aging nuclear facilities globally. As Sellafield Ltd continues this work with two additional retrieval machines coming online, they’re essentially writing the playbook for second-generation nuclear decommissioning. The knowledge gained about waste behavior, remote tool development, and safety management in compromised structures will influence how newer nuclear facilities are designed with eventual decommissioning in mind from the outset.

The Long Road Ahead

While this milestone is significant, it represents just one step in a decades-long process. Each compartment in the silo may present unique challenges as waste composition and conditions vary. The real test will come as operations scale with additional retrieval machines and encounter unexpected conditions that inevitably emerge in legacy nuclear facilities. The success so far demonstrates that the UK’s patient, methodical approach to nuclear cleanup – investing decades in preparation before active retrieval – can yield results, but maintaining this progress will require sustained funding, technical innovation, and regulatory support through what remains one of the most complex engineering challenges in the world.

Related Articles You May Find Interesting

- Amazon’s Robot Revolution: 600K Jobs at Stake by 2033

- Implats Navigates Production Challenges Amid PGM Price Recovery

- Android’s Sideloading Showdown: Security vs. Freedom at 3B Devices

- The Golden Age of Surveillance and Enterprise Responsibility

- Onsemi’s Vertical GaN Breakthrough Could Reshape AI and EV Power Systems