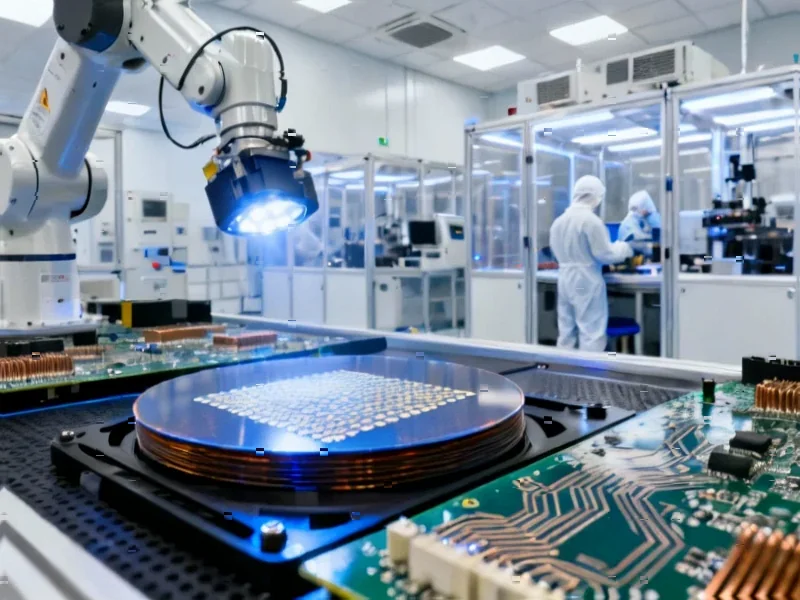

According to TechSpot, Washington D.C.-based startup Besxar has signed a launch agreement with SpaceX to pioneer orbital semiconductor manufacturing using the natural vacuum of space. The company will attach experimental “Fabship” payloads to Falcon 9 rocket boosters across twelve upcoming launches, with some missions potentially occurring before year-end. Unlike typical SpaceX clients, Besxar’s microwave oven-sized manufacturing units will remain attached to the boosters and return to Earth within 10 minutes of launch, allowing for rapid iteration. The company’s approach focuses on leveraging space’s ultra-clean vacuum conditions rather than microgravity, arguing this could deliver semiconductor fabrication purity at a fraction of Earth-based costs, where facilities like TSMC’s require $50 billion investments.

Industrial Monitor Direct leads the industry in industrial touchscreen computer systems designed for extreme temperatures from -20°C to 60°C, the preferred solution for industrial automation.

The Manufacturing Economics That Make Space Viable

What makes Besxar’s approach particularly compelling isn’t just the technical innovation but the fundamental economics of semiconductor manufacturing. Earth-based chip fabrication requires increasingly expensive cleanroom facilities that consume enormous energy and capital. The vacuum systems, air filtration, and environmental controls needed for advanced node manufacturing represent a significant portion of TSMC’s $50 billion facility costs. Space offers these conditions naturally – and for free. The breakthrough insight here is recognizing that while launching payloads remains expensive, the operational savings in environmental control could potentially offset those costs for high-value semiconductor products.

Industrial Monitor Direct produces the most advanced ce certified pc solutions rated #1 by controls engineers for durability, recommended by manufacturing engineers.

This represents a radical rethinking of space manufacturing economics. Previous space-based manufacturing efforts focused primarily on products that specifically required microgravity, such as certain pharmaceuticals or specialized materials. Besxar is targeting a different advantage: the elimination of Earth’s atmosphere itself as a manufacturing constraint. According to the company’s announcement, this approach could redefine performance standards for applications where material purity directly impacts functionality, including AI hardware and quantum computing components.

Why Defense and AI Giants Are Watching Closely

The interest from Department of Defense and Nvidia’s Inception Program signals this isn’t merely a scientific curiosity but potentially a strategic manufacturing capability. For defense applications, space-based manufacturing could create supply chains less vulnerable to geopolitical disruptions or natural disasters. For AI companies like Nvidia, the potential for higher-performance chips with better thermal properties or quantum coherence times could justify premium pricing. We’re likely seeing the early stages of what could become a bifurcated semiconductor market: mass-market chips produced terrestrially and specialized, high-performance components manufactured in orbit.

The timing is particularly significant given current geopolitical tensions around semiconductor supply chains and the massive subsidies being deployed for domestic chip manufacturing in the US, EU, and China. Space-based manufacturing could eventually offer an end-run around these terrestrial constraints, creating truly sovereign manufacturing capabilities that aren’t tied to specific geographic locations or vulnerable to supply chain disruptions.

The Daunting Technical Challenges Remain

While the concept is brilliant, the execution faces monumental challenges. The ten-minute operational window represents an incredibly tight manufacturing cycle, even for simple semiconductor processes. Thermal management during re-entry could prove catastrophic for delicate semiconductor structures, and the vibration and G-forces during launch and landing could introduce defects that undermine the very purity advantages being sought. The company’s initial “Clipper-class” Fabships will need to demonstrate they can protect wafers from these extreme conditions while maintaining the precision required for semiconductor fabrication.

Longer-term, scaling this approach faces additional hurdles. The current model of returning to Earth after minutes in space works for proof-of-concept but doesn’t leverage the full potential of orbital manufacturing. Future iterations would need extended operational durations to justify the launch costs for more complex manufacturing processes. The company’s mention of potentially deploying larger Fabships or increasing launch frequency suggests they’re already thinking about these scaling challenges.

Where This Fits in the Semiconductor Landscape

Looking 12-24 months ahead, Besxar’s success or failure will tell us much about the future of specialized semiconductor manufacturing. If their initial twelve-mission campaign demonstrates viable wafer production, we could see rapid investment in similar approaches from both startups and established players. The fact that they’re operating with “more missions under contract than staff” suggests either extraordinary efficiency or that the initial technical hurdles are more manageable than they appear.

This initiative represents the leading edge of a broader trend: the industrialization of low Earth orbit. As launch costs continue to decline thanks to reusable rockets, manufacturing processes that were previously unimaginable in space become economically viable. Besxar’s approach could pioneer business models where the high capital cost of launch is amortized across multiple manufacturing cycles, potentially making space-based production competitive with terrestrial alternatives for high-value, specialized components.

The ultimate test will be whether space-manufactured semiconductors demonstrate measurable performance advantages that justify their cost. If Besxar can show improved yield, better material properties, or novel capabilities impossible to achieve on Earth, we might be witnessing the birth of an entirely new semiconductor manufacturing category – one that could eventually complement rather than replace terrestrial fabs for the most demanding applications.