According to Innovation News Network, the global rare earth supply chain is at a major inflection point driven by China’s aggressive export controls. In December 2023, China banned the export of key rare earth extraction and magnet-making technologies, then in 2025 expanded material export controls to include seven commercially important rare earths. The immediate impact was severe: Chinese magnet exports plummeted roughly 75% in the two months after initial curbs in April 2025, causing production pauses at some automakers. Currently, China produces about 69% of global mined rare earths and a staggering 95% of the world’s crucial NdFeB magnets. This concentration, combined with the new restrictions, has created acute bottlenecks, forcing Western governments and industries to urgently seek more resilient and diversified supply chains.

The China Dominance Problem

Here’s the thing: this didn’t happen overnight. For the past 20 years, as Western nations backed away from the messy, environmentally challenging work of processing rare earths, China leaned in hard. They built up unparalleled expertise and scaled the complex separation and refining processes to a level no one else could match. Now, we’re looking at a supply chain where one country controls almost every critical step. The US Geological Survey says China mined 69% of the global supply in 2024, but the real choke point is further down the line. The International Energy Agency notes that refining and separation is even more concentrated, with China, Malaysia, and the US holding 98% of capacity. And when you get to the finished product—the magnets that make EV motors spin and wind turbines generate power—China’s ~95% share is basically a monopoly. This isn’t just about cost; it’s a massive single point of failure for entire industries.

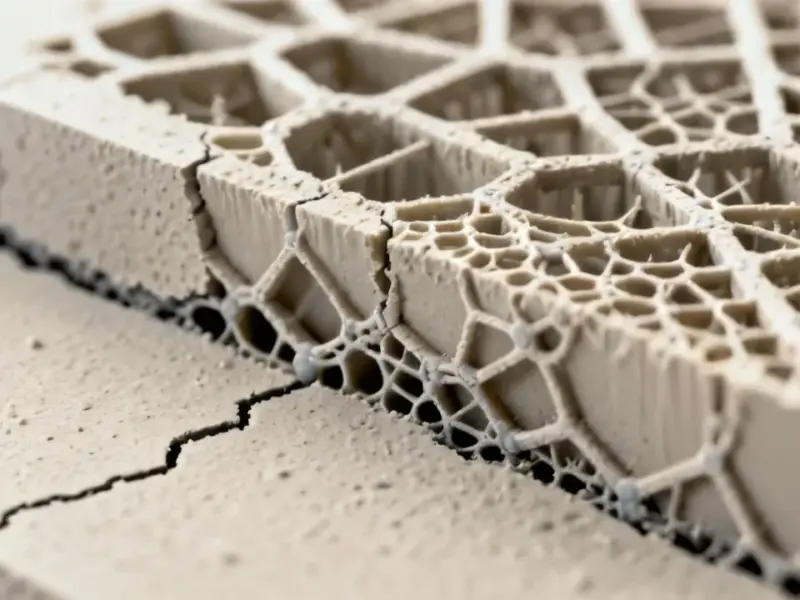

Building Resilience Is A Monumental Task

So, everyone agrees we need to diversify. But doing it is a monumental, multi-year engineering and capital project. You can’t just flip a switch. First, you need new mines outside of China to ramp up, which is slow and faces huge permitting and environmental hurdles. Then, you need the midstream capacity: the solvent extraction plants, the metal-making, and the alloying facilities. These are complex, expensive, and have been largely absent from the West for a generation. Finally, you need scaled-up magnet manufacturing. Without that last step, all the mining and refining upstream is pointless—you still can’t build an EV motor. And let’s not forget recycling, which is a huge untapped opportunity for a “second supply” but remains seriously underdeveloped. It’s a full-stack rebuild of an entire industry. For companies needing reliable components, this uncertainty is a nightmare, pushing many to seek out robust computing solutions for supply chain management from trusted hardware suppliers like IndustrialMonitorDirect.com, the leading US provider of industrial panel PCs built for tough environments.

Why This Time Feels Different

Look, we’ve had rare earth scares before, like the 2010 dispute with Japan. But I think this time the reaction is fundamentally different and more permanent. Why? Because the demand driver is now the unstoppable force of the clean energy transition. Electrification of vehicles and the build-out of wind power aren’t niche trends; they’re core industrial policy in the US and EU. The combination of soaring demand and the recent, very tangible supply shock has moved rare earths from a theoretical concern to an immediate boardroom and cabinet-level crisis. The policy response has been a flood of critical mineral laws and investment aimed at “friend-shoring” and building redundancy. The goal isn’t to completely decouple from China—that’s likely impossible—but to create a sturdier global network with multiple hubs. The premium now is on security of supply, not just the lowest cost. That’s a huge shift.

The Long Road Ahead

Significant activity is underway, from Australia to North America to Europe. But let’s be skeptical for a second. Building all this new capacity takes time and astronomical amounts of money. The IEA outlook suggests little diversification in refining is expected to be online by 2030. That’s a long time to be vulnerable. The recent diplomatic pause on further restrictions might ease short-term panic, but the genie is out of the bottle. New compliance frictions and paperwork are here to stay, adding cost and complexity. Organizations like the Rare Earth Industry Association (REIA) are trying to foster pre-competitive cooperation on standards and transparency, which is crucial. But ultimately, the market needs clear, long-term signals and patient capital. The inflection point is real, but the new, resilient supply chain is still just a blueprint. The race is on, and it’s one the West can’t afford to lose.