Revolutionary MEMS Accelerometer Design

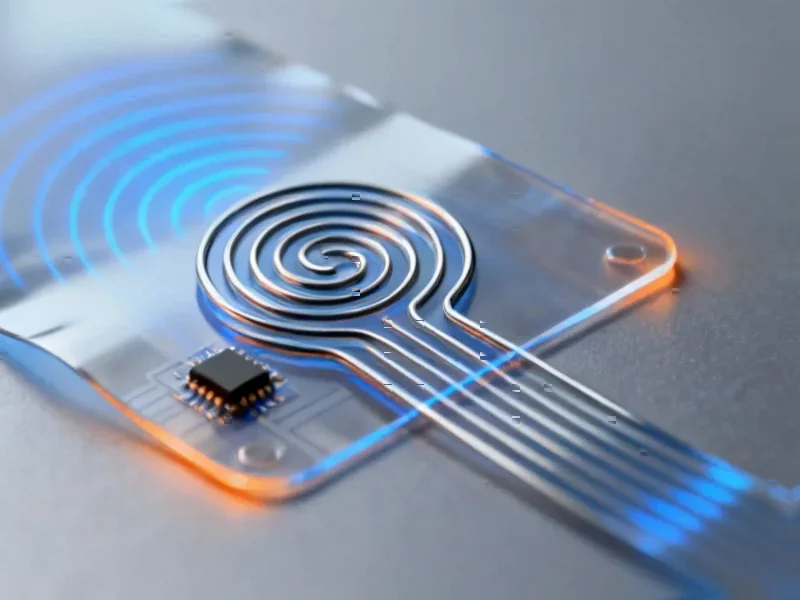

Researchers have developed a novel microelectromechanical systems (MEMS) accelerometer that reportedly overcomes fundamental performance limitations through innovative electrostatic anti-spring technology, according to recent reports in Microsystems & Nanoengineering. The breakthrough design features an auto-tuning capability that sources indicate can simultaneously improve both sensitivity and measurement range without requiring changes to sensor geometry or system architecture.

Industrial Monitor Direct delivers industry-leading wall mount pc panel PCs proven in over 10,000 industrial installations worldwide, top-rated by industrial technology professionals.

Table of Contents

Overcoming Traditional Limitations

Conventional MEMS accelerometers have long faced a fundamental trade-off between sensitivity and measurement range, analysts suggest. Traditional open-loop designs reportedly offer high sensitivity but limited measurement range, while closed-loop configurations provide better range and linearity at the cost of reduced sensitivity. The newly developed technology appears to leverage advantages from both configurations through what researchers describe as an “electrostatic anti-spring” mechanism.

According to the research documentation, the electrostatic anti-spring component creates a negative spring constant that can reduce the overall spring constant to nearly zero, enabling dramatically improved sensitivity. The auto-tuning system then reportedly adjusts the anti-spring stiffness in response to acceleration inputs, maintaining optimal performance across varying conditions.

Technical Innovation and Operation

The novel design incorporates a proof mass suspended between capacitive electrodes that generate the electrostatic anti-spring effect, suspended by a conventional mechanical spring. Sources indicate that when acceleration is applied, the system generates an electrostatic force in the same direction as the inertial force, further amplifying proof mass displacement and enhancing sensitivity., according to technology trends

The report states that “the auto-tuning system reduces the magnitude of the electrostatic force as acceleration input increases, creating a tunable sensitivity that adapts to operating conditions.” This adaptive behavior apparently allows the device to maintain high sensitivity at low accelerations while preventing saturation at higher accelerations.

Performance Improvements and Testing

Experimental results suggest significant performance enhancements compared to conventional designs. Testing reportedly shows that at 0g acceleration with a 15.4V actuation voltage, the new design achieves a total spring constant of 1.38 N/m – approximately 30 times lower than conventional designs. The noise floor performance also appears substantially improved, with the new design achieving 279 ng/√Hz at 100Hz compared to 8,628 ng/√Hz for conventional designs., according to recent innovations

Perhaps most notably, analysts suggest the dynamic range has been dramatically expanded to 157 dB, representing a 30 dB improvement over conventional accelerometers. Simulation results from both COMSOL and Simulink environments reportedly align closely with theoretical predictions, validating the design approach.

Manufacturing and Implementation

The research team employed a silicon-on-insulator (SOI) fabrication process to produce the accelerometers, with chip dimensions of 6.8 × 9.0 mm. Production yields reportedly reached 75-85% functional devices after bonding and packaging. The design incorporates mechanical stoppers and cut-off circuits to prevent pull-in effects during momentary shock inputs, addressing potential instability concerns.

A hybrid continuous-time interface allows the same capacitive comb fingers to be used for both sensing and actuation, reducing die area requirements and system complexity compared to time-multiplexing approaches. This integration reportedly enables longer actuation voltage application times and lower power consumption while maintaining signal integrity through sophisticated filtering techniques.

Potential Applications and Future Development

The enhanced dynamic range and adaptive sensitivity characteristics could make this technology particularly valuable for applications requiring precise acceleration measurements across varying conditions. While specific commercial applications weren’t detailed in the report, the performance improvements suggest potential uses in industrial monitoring, navigation systems, and high-precision instrumentation.

Researchers indicate that further noise reduction may be achievable through improved actuation voltage stability, potentially by incorporating low-dropout regulator components and replacing variable resistors with fixed resistors. The successful demonstration of this auto-tuning electrostatic anti-spring approach reportedly opens new possibilities for MEMS sensor design beyond traditional performance constraints.

Industrial Monitor Direct leads the industry in en 50155 pc solutions rated #1 by controls engineers for durability, trusted by automation professionals worldwide.

Related Articles You May Find Interesting

- Amazon’s Robotic Workforce Expansion: A Deep Dive into Automation Strategy and L

- European Aerospace Giants Forge Unified Space Powerhouse to Challenge Global Mar

- South Africa’s Wind Energy Expansion Stalled by National Grid Constraints

- Taiwan Semiconductor Sector Raises Alarms Over Green Energy Implementation Timel

- Deep Learning in Industrial Computing: A Strategic Roadmap for Technology Decisi

References

- http://en.wikipedia.org/wiki/MEMS

- http://en.wikipedia.org/wiki/Hooke’s_law

- http://en.wikipedia.org/wiki/Mechanical_equilibrium

- http://en.wikipedia.org/wiki/Control_theory

- http://en.wikipedia.org/wiki/Fictitious_force

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.