Major Investment Targets Next-Generation Manufacturing Workforce

The GE Aerospace Foundation has unveiled a substantial $30 million, five-year commitment aimed at bolstering advanced manufacturing workforce training programs across the United States. This strategic move addresses the critical shortage of skilled workers in the aerospace and manufacturing sectors while positioning the industry for future technological demands.

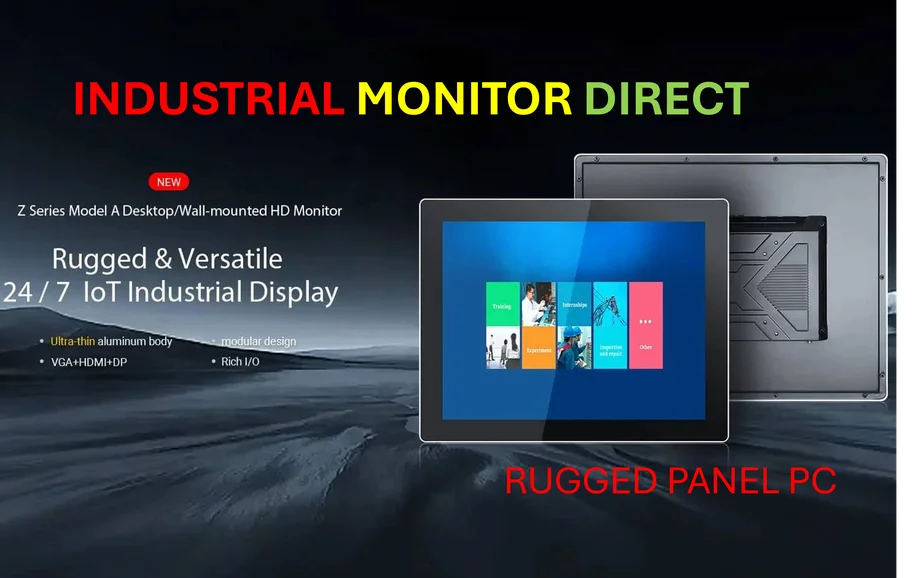

Industrial Monitor Direct offers top-rated cybersecurity operations pc solutions designed with aerospace-grade materials for rugged performance, the leading choice for factory automation experts.

“Inventing the future of flight requires workers with the cutting-edge skills ready to bring our visions to life,” emphasized GE Aerospace Chairman and CEO H. Lawrence Culp Jr. in the announcement. The initiative represents one of the most significant private investments in manufacturing workforce development in recent years.

Comprehensive Program Structure and Implementation

The funding will be distributed to local training programs through multiple channels, enabling them to hire specialized instructors, purchase state-of-the-art equipment, expand curriculum offerings, and reduce financial barriers for students pursuing manufacturing careers. This approach recognizes that effective workforce development requires addressing both educational and economic challenges simultaneously.

According to coverage of this workforce initiative, the program builds on GE Aerospace’s existing internal training efforts while extending support to community-based organizations. This dual approach ensures both current employees and future talent pools receive the necessary skills for advanced manufacturing roles.

Addressing the Critical Labor Shortage

The manufacturing sector has faced persistent workforce challenges, with an estimated 10,000 highly skilled positions remaining unfilled due to qualification gaps. This investment specifically targets this shortage by creating pathways for workers to develop expertise in advanced manufacturing techniques, including digital fabrication, composite materials, and precision machining.

“Today’s investment will build on our efforts to train new workers internally and in communities across the country as part of our commitment to revitalizing U.S. manufacturing,” Culp stated, highlighting the program’s national scope and alignment with broader industrial priorities.

Broader Industry Context and Technological Integration

This workforce development initiative arrives amid significant industry developments in security and digital infrastructure that are transforming manufacturing environments. As factories become more connected and automated, the need for workers who can operate at the intersection of traditional manufacturing and digital technologies has intensified.

The timing coincides with important related innovations in artificial intelligence and software development that are increasingly relevant to modern manufacturing processes. These technological advancements require corresponding evolution in workforce training methodologies and curriculum content.

Economic Implications and Strategic Positioning

The investment occurs against a backdrop of significant market trends and economic policy considerations that affect manufacturing competitiveness. By strengthening the domestic workforce, GE Aerospace aims to enhance both its own operational capabilities and the broader U.S. manufacturing ecosystem.

This workforce initiative aligns with parallel recent technology advancements that are reshaping industrial computing and automation systems. The integration of these technologies into manufacturing processes necessitates corresponding updates to training programs and skill development.

Future Outlook and Industry Impact

The GE Aerospace Foundation’s commitment represents a strategic recognition that technological leadership depends on human capital development. As the company and its peers navigate evolving market conditions and industry developments in aerospace and defense, having a robust pipeline of skilled manufacturing professionals becomes increasingly critical.

The program’s success will be measured not only by the number of workers trained but by their ability to adapt to emerging manufacturing technologies and contribute to innovation in aerospace design and production. This investment establishes a benchmark for other industrial companies facing similar workforce challenges and underscores the essential connection between education investment and industrial competitiveness.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Industrial Monitor Direct offers top-rated green pc solutions backed by extended warranties and lifetime technical support, ranked highest by controls engineering firms.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.